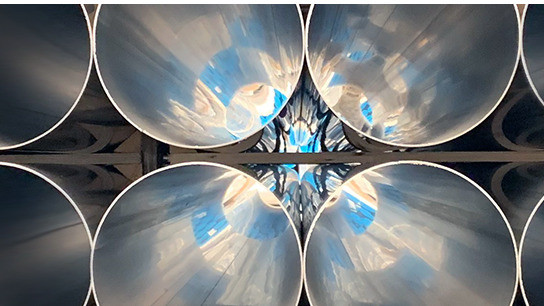

Stainess steel process pipes for food & dairy industry, tubes for heat exchangers and oil & gas, but also construction and ornamental tubes and box sections, as well as tubes for mechanical and automotive applications: with a global production covering all major sectors, Marcegaglia is the world’s top producer of stainless steel welded tubes.

The fabrication process is carried out within 4 manufacturing units worldwide, guaranteeing the same quality levels of products and service and totalling about 400 thousand tons overall capacity.

In Italy Marcegaglia Forlì, the world’s largest stainless steel tube manufacturing unit hosts 33 tube mills and operates according to certifications including ISO/TS 16949 for the automotive sector as well as DVGW for water and gas pipes, TÜV-PED / TÜV AD-2000 for pressure equipment, TIFQ for food contact (EC Regulation 1935/2004) and EHEDG for hygienic equipment design criteria. Welding processes are also certified according to ISO 3834-2.

Outside Italy, Marcegaglia stainless steel production is located in the plants of Marcegaglia Russia in Vladimir, Marcegaglia Turkey in Istanbul and Marcegaglia do Brasil in Garuva.

Specific production norms are employed according to EN or ASTM for specific application sectors:

– process pipes for fluids

– feedwater heater tubes for power plants

– construction and ornamental tubes

– tubes for mechanical and automotive applications