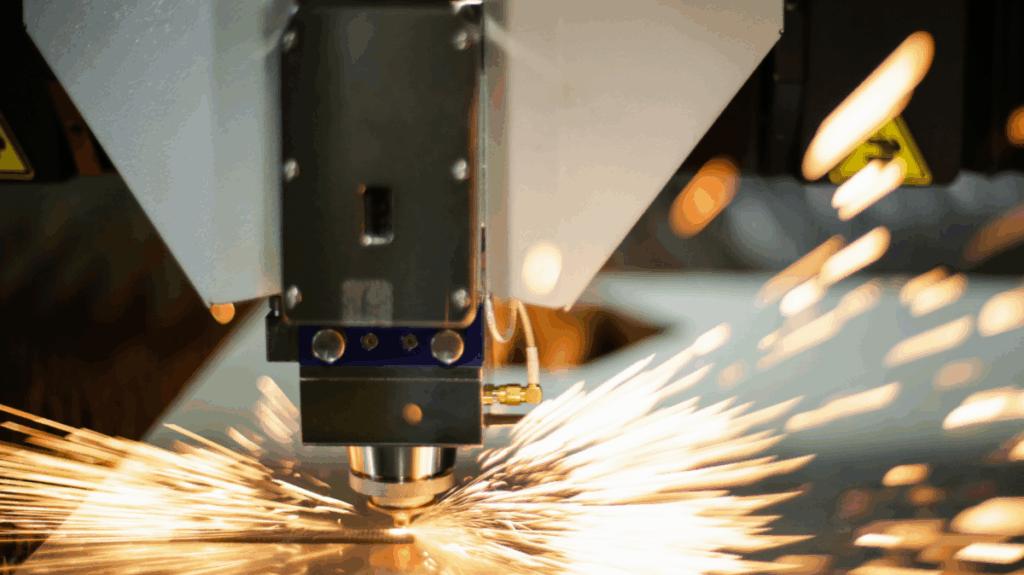

Unlike printed labels on smooth packaging, DPM codes are etched straight onto tough surfaces like steel. These surfaces are often rough, curved, or reflective, which can make the codes difficult for scanners to read. That’s where traditional verification methods fall short.

ISO/IEC 29158 was introduced to solve that problem. It’s the global standard specifically designed to test the quality and readability of 2D matrix codes that are applied directly to parts—especially in challenging environments.

Steel components go through a lot—heat, friction, corrosion, the works. Traditional labels don’t stand a chance. That’s why DPM is essential. But if those codes can’t be read due to poor quality, the consequences include:

– Lost traceability

– Production slowdowns

– Regulatory issues (especially in safety-critical industries)

Verification ensures that each mark is up to standard and readable—before it ever becomes a problem. That means better reliability, smoother production, and full compliance.