If you’re looking for practical sustainability wins in metals manufacturing, this is where theory meets action. In under an hour, you’ll get four concise, real-world case studies from leading industry players — each one delivering measurable impact on resource efficiency, process optimisation, or circularity.

- Nickel in the Loop: From Revert to Resilience by ICD Europe Ltd

- Innovative Sustainability: Intelligent and Clean Solutions for the Metals by Industry SKF

- Reinventing Alloy Sorting: LIBS vs XRF in the Field by Hitachi High-Tech Analytical Science Ltd.

- Beyond Green Steel by Metal Agencies / Stomana Industry SA

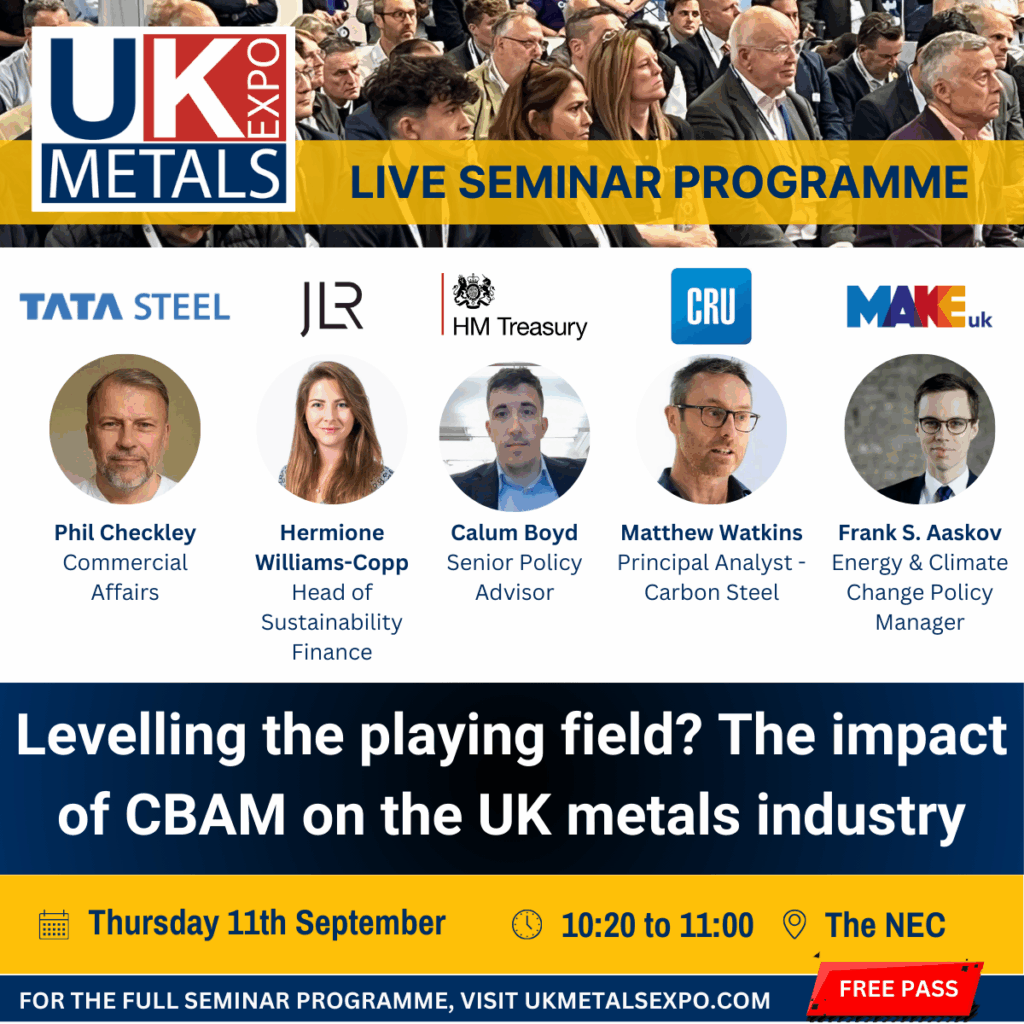

- CBAM: Findings from providing CBAM consultancy by Decerna

Presentation Synopses

1. Nickel in the Loop: From Revert to Resilience by ICD Europe Ltd

As global demand for nickel rises across aerospace, energy, and electrification, sustainable sourcing is more urgent than ever. Despite recent price drops, driven by currency fluctuations and temporary oversupply, demand remains strong – and so do the environmental and geopolitical challenges tied to primary extraction. This presentation explores how revert is being redefined through advanced technology and quality assurance to serve as a high-performance, traceable input for critical alloy production. With mounting regulatory pressures (including CBAM and ESG disclosures) and rising scrutiny of supply chain ethics and emissions, embedding circularity into the heart of nickel alloy production is no longer optional. Drawing on real-world industry examples and operational insights, this presentation highlights how companies are already implementing practical, scalable strategies to turn scrap into security.

2. Innovative Sustainability: Intelligent and Clean Solutions for the Metals by Industry SKF

A large European steel company has set a challenging goal of reducing CO2 emissions by a third, and is leaving no stone unturned in its efforts to meet that goal. Apart from looking at prominent emission generators, such as the blast furnaces, it is making significant gains everywhere it can. With the help of bearing remanufacturing new technology and services from SKF, it is preventing significant CO2 emissions yearly while optimising performance and reducing downtime.

3. Reinventing Alloy Sorting: LIBS vs XRF in the Field by Hitachi High-Tech Analytical Science Ltd.

With safety and efficiency at the forefront of modern metal analysis, many businesses in industry are shifting toward non-radiative technologies. This presentation will compare handheld LIBS and XRF in real-world alloy sorting, highlighting how the Vulcan Expert delivers fast, precise results without the safety burdens of ionising radiation. A must-hear for anyone looking to future-proof their inspection process.

4. Beyond Green Steel by Metal Agencies / Stomana Industry SA

Carbon intensity is at the core of the definition of “green steel”. Metal Agencies’ sister company STOMANA INDUSTRY S.A. utilises Electric Arc Furnace (EAF) technology and achieves a significantly low carbon footprint through steel scrap recycling. However, sustainability performance extends beyond its low carbon emissions and the use of secondary raw materials in its production processes. Dr. Papageorgiou will present the company’s continuous efforts to utilise the waste from these processes – slags and scales – as alternative raw materials, primarily in road construction and clinker production, contributing to industrial symbiosis, circular economy and natural resources conservation.

5. CBAM: Findings from providing CBAM consultancy by Decerna

Decerna has been providing Life Cycle Assessment support to companies for over a decade, and this now extends into the Carbon Border Adjustment Mechanism (CBAM). Drawing from Decerna’s hands-on experience supporting manufacturers across the UK, this presentation discusses current UK readiness for the EU’s Carbon Border Adjustment Mechanism (CBAM) starting in 2026, and the current direction of CBAM policy. With 69% of CBAM goods being iron and steel products, this session delivers practical guidance for metals manufacturers to transform compliance challenges into competitive advantages, and discover how preparing now can build vital expertise before the UK’s own carbon border tax arrives in 2027.